- Water Treatment SystemThis water treatment system is a process to harvest potable drinking water (pure water, mineral water) through a series of water purifiers or water treatment equipments. Original water, such as rain water, river water, and dam water, needs to be physics and chemical treated before it becomes potable drinking water, including pure water and mineral water...

- Bottle Filling MachineThis CGF series bottle filling machine is a kind of 3-in-1unit rinsing filling capping machine for producing potable drinking water like pure water, mineral water etc. The device incorporates rinsing, filling and capping into one and is a kind of full-automatic equipment. It is suitable for producing PET and plastic bottled mineral water and purified water. The method of filling adopts gravity or micro-pressure...

- Conveyor System1. Modular design: modular design is characterized by making products more diverse, simple and more changeable with other components, and install and maintenance convenient. According to specific requirements of users, different production capacity, and bottle shapes, it can also be combined into different conveying methods, module units, motors and control ways, thus this system enjoying high flexibility...

- Packaging SystemThe packaging system is designed for packaging production line of various beverages. This system includes production date printer, labeler, heat shrink membrane overwrapping, and carton packer, etc. Besides, this packaging system has many different packing methods, thus this system makes it not only easy for transportation, but also effective to promote popularity of its brand...

CGF Series Bottled Water Filling Line (Water Bottling Equipment)

Description:

The CGF series bottled water filling line is used to fill mineral water or purified water into PET bottles from 200ml-2500ml. Different models can satisfy various requirements of output from 5000B/H to 30000B/H. It is a kind of production line for producing potable drinking water (purified water, mineral water).

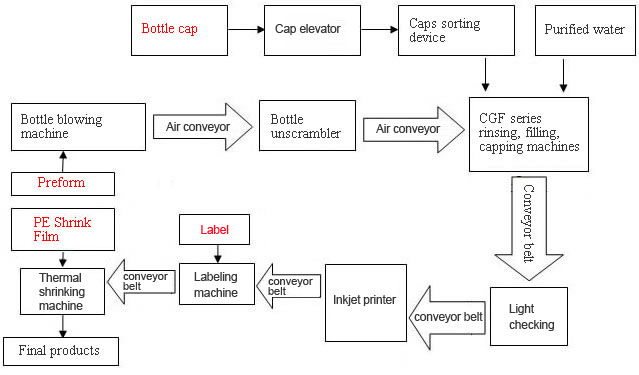

Our water filling production line (water bottling equipment) mainly consists of water treatment equipment (water filtration sterilizers system), filling system, packaging system and conveyor system. The production process is like this: bottle blowing machine produce new bottles from bottle preform. New bottles go into rinsing, filling, capping mono-bloc through air conveyor. The water treatment system supply purified water for bottle washing and filling. After capping in the mono-bloc, bottled water go into packaging system for production date, labeling and final package through belt conveyor. The whole process is automaticly controlled by PLC. The operator could adjust the capacity per hour by touch screen on the control box easily.

Processing Flow of Bottled Water Filling Line:

Notice: Customers themselves need to provide the red print part devices.

Founded in 2006,  , is a leading manufacturer and supplier of bottled water filling line (water bottling equipments) in China. Here in Lantypc, we mainly offer water filling line, juice filling production line, carbonated drink filling line and related equipments including rinsing filling capping machine, beverage mixer, purified mineral water production line and other machines. We offer installing and debugging services of our devices and staff training for factories abroad and OEM service. For more guides of bottled water filling line, please contact us.

, is a leading manufacturer and supplier of bottled water filling line (water bottling equipments) in China. Here in Lantypc, we mainly offer water filling line, juice filling production line, carbonated drink filling line and related equipments including rinsing filling capping machine, beverage mixer, purified mineral water production line and other machines. We offer installing and debugging services of our devices and staff training for factories abroad and OEM service. For more guides of bottled water filling line, please contact us.

Related products

- Barreled Water Filling LineThis TXG series 3/5 gallon barreled water filling line is mainly used to produce bottled water with volume from 3 gallon to 5 gallon. And different models can offer production capacity from 100 to 2000 B/H. The whole production process operates as follows:

1. Empty barrel are conveyed stably by conveying belt into decapping machine...

landy.industry20@gmail.com

landy.industry20@gmail.com